Woodhead - planning the third tunnel

For just a touch over a century, from 1845 through to 1953, the twin bores of Woodhead Tunnel served their various owner railway companies very well. Set high in the Pennines on the route from Sheffield (Victoria) to Manchester (London Road) [subsequently Manchester (Piccadilly)], they pierce the backbone of England almost 1000ft above sea level. After a great many years service, the mortar of the stone lining of the twin bores started to 'disappear' (to use the official term). Despite the very best efforts of both the railway company and the eventual contractors, Messrs Balfour Beatty, the problem reached such a state that some form of replacement started to be seriously considered.

The beginning of the end.

The old tunnels had borne the brunt of the exhaust from almost uncountable steam engines hauling heavy trains on fairly fierce gradients for a long, long time. Because of the structure of the ground through which they passed, the original builders had taken the decision to line both bores throughout with stonework using mortar bonding and eventually this mortar was to be their downfall (not quite literally, but certainly in operational terms). The acid effect of the exhaust fumes, and don't forget that we are talking an average of 80 trains per day through each tunnel and rather minimal clearing of the exhaust (of the five ventilation shafts originally installed, only two actually worked in a positive updraught manner), eroded the mortar. Strenuous efforts came to naught. Weekend possessions by the engineers proved woefully insufficient, the wrenching decision was made in 1946 to give the civil engineering department total possession of each bore (alternately) for a period of nine months. The intention was that by enabling continuous, uninterrupted work on the linings by day and night, the situation could be remedied. In the event, at the end of this period a very generous extension of time was required to complete the outstanding work. Operating difficulties created by single line working and diversions to other routes made this extension impracticable. (The cost of diverting revenue-producing trains over another railway company's metals [this was pre-Nationalisation] must have been absolutely phenomenal; what a monumental decision to have to make and to have to negotiate!). The only practicable solution to the problem was the construction of a new tunnel and the abandonment of the old ones. Three alternatives were considered:-- a new single line tunnel and repair one of the existing ones.

- two new single line tunnels.

- a new double line tunnel

The estimated costs of these were, respectively, 104%, 143% and 100% With these costings in mind, the civil engineers recommended to the management of L.N.E.R that the construction of a new twin line tunnel be undertaken. The Board accepted the proposal and the necessary Parliamentary powers were enacted in the L.N.E.R. Act of 1947. Sir William Halcrow & Partners were appointed Consulting Engineers and undertook details of design and also supervised work on site. This work was under the direction of the Company's Civil Engineer J. I. Campbell M.I.C.E., who saw the work through to it's completion.

External factors

In addition to planning the actual tunnel, there were quite a number of other factors which had to be taken into consideration. Nothing is ever straightforward.

- The protection of Manchester Corporation.'s water catchment area.

- The requirement for Manchester Corporation's Medical Officer to examine any worker.

- The siting of spoil tips from the tunnelling.

- The remodelling of approach track layouts at both ends of the tunnel.

- New platforms and station buildings at both ends of the tunnel.

- Two new signal boxes.

- A new overline bridge at Dunford Bridge to carry Windleden Lane over the line.

- A new underline bridge at Woodhead to take the remodelled lines over the River Etherow.

- Stationmaster's houses at Woodhead and Dunford Bridge.

- The demolition of certain old cottages at Dunford Bridge.

- The provision of accomodation for up to 1500 workers, with accompanying facilities.

- The provision of sewage facilities for the camp (it was specified in the Act of Parliament that this provision be left in place on completion of the works and removal of the 'camp'. It was taken over by Penistone UDC but no longer appears to be present.)

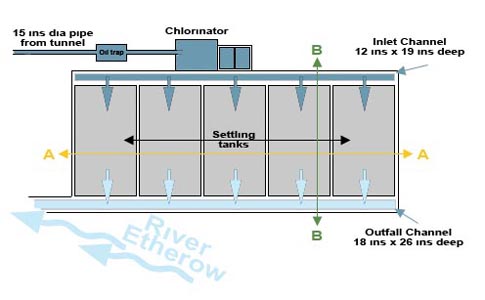

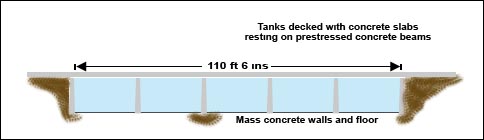

The 1947 Act contained clauses to cover a number of these points. Because of the string of reservoirs down the river valley from just below Woodhead right down to Tintwhistle, it was required that all water arising from the new tunnel should be purified before being discharged into the River Etherow. Water drained from the tunnel passed through an oil filter, then a chlorinator before reaching 5 concrete settling tanks. These were made of mass concrete (walls and floors), with decking of concrete slabs resting on pre-stressed concrete beams. The total fall through the plant was 8 inches.

Plan view of tunnel effluent

settlement tanks at Woodhead.

Cross-section A-A of settlement tanks

When the original tunnels were bored, there was an outbreak of cholera (1849) which claimed the lives of 28 workmen (this was actually part of the second and most serious of four cholera pandemics which swept the UK in the 19th Century, this outbreak killing 53,000 people overall {including members of the writer's family}). A similar cholera outbreak during the boring of Totley tunnel (circa 1890) highlighted the potential dangers, which by this time had been closely allied with contaminated water supplies. Another requirement of the Act, probably with this in mind, was that Manchester Corporation's Medical Officer had the right to examine 'any person employed in the construction of the works to avoid the risk of contamination of the water supply'.

A further requirement was observation of the Town & Country Planning Acts with regard to the siting and formation of the spoil heaps. The two previous tunnels had filled all the immediate local sites so spoil was transported

- further up the Etherow valley from Woodhead.

- along the A628 part way to Salter's Brook Bridge.

- distributed around the site of the single shaft (which was adjacent to No. 3 shaft of the old tunnels).

- used to in-fill Smallden Clough where the stream was diverted into culverts.

Design and Location

Although no technical accounts could be found of the construction of the old tunnels, one record did survive which was to prove invaluable. In 1845, the Resident Engineer Mr W. A. Purdon had deposited with the Geological Museum (South Kensington) a large and detailled longitudinal section along the original tunnel and through the 5 shafts. This described the strata encountered and the limits and locations of geological features. Very full use was made of this record and very valuable deductions could be made based on a record of the geology a very small distance away from where the new tunnel was to be bored.

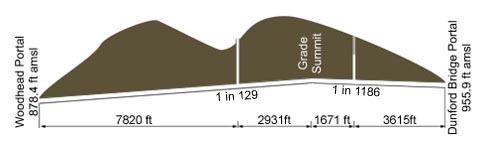

Woodhead Tunnel, showing location of 467ft deep shaft, grade summit

at 960.6ft amsl and location of 45° stope to old No. 5 airshaft.

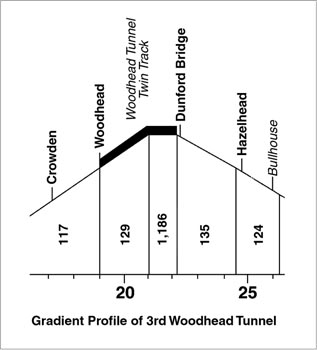

To a degree, at Woodhead certainly, the terrain dictated location. The very narrow Etherow Valley at that point would have required very extensive groundwork immediately adjacent to a very busy line - not in the least desirable! What was decided was that the new tunnel would parallel the old ones with the centreline 100ft from the centreline of the old down line. One major difference was that, while the old tunnels are arrow straight and rise on a steady gradient of 1 in 201, the new one would reach a summit within the tunnel itself, with a steeper rise at the Woodhead end (1 in 129) and a slight fall at Dunford Bridge (1 in 1,186). One thought behind this relatively unusual step was the reincarnation of the old idea of possibly having two trains on the line at the same time.

The new tunnel, because of topographical (and hence cost) constraints, couldn't be straight like the predecessors - apart from anything else it had to link into existing trackwork! At the Woodhead end, the tunnel curves in the last 600 feet (almost 183 metres) on a radius of 40 chains (804.673 metres) to permit the new tracks to be connected to the existing alignment. At Dunford Bridge, where the valley is less restricting, the alignment curve is outside the tunnel.

Gradient profile of Woodhead double line tunnel.

tunnel & the approaches.

Planning problems.

Integrating the new tunnel into an existing, and very busy, route was never going to be easy. The simple fact of blasting so close to exisitng tunnels had to be taken very cautiously indeed and gave some cause for concern.

Throughout the blasting, an engineer was stationed within the old down tunnel to check the effects of the nearby charge-firing. Through the great majority of the tunnel a minimum separation of 77ft is maintained but at the Woodhead end, where terrain was a major factor, it came down to 27ft. This last portion was through blocky sandstone and very considerable care was taken. Fortunately there was no evidence of any disturbance to the existing working tunnel although, given the reluctance of the old bores to clear of exhaust, inspection can't have been a pleasant job!

One thing which wasn't anticipated was at the Woodhead end. It had already been decided that fairly major remodelling of the station and facilities here would be necessary. What wasn't anticipated in the early stages was the alignment of the bridges. The plan had been to build the new bridge over the River Etherow on a 40-chain (803m) radius, complementing the radius through the new portal and aligning the new track with the old for a smooth transition.

Starting in 1936, the Sheffield - Wath - Manchester line had started to be electrified throughout using a 1,500v D.C. supply (the only time this configuration was used on railways in England). The new tunnel was designed with this in mind (the old ones arguably didn't have sufficient clearance for the overhead catenaries). The intention was always that the new tunnel would be electrified from the outset and 'ventilation' was less necessary than otherwise.

It became clear, when surveying for the Etherow overbridge, that clearances were insufficient and, in fact, a proposal was put forward that initially only the down side of the bridge be completed. Down (steam) trains would then run through the new tunnel and up trains through the old single bore until such time as the new up portion of the overbridge could be completed. This was impractical and alternative answers were sought.

The problem was that the up portion of the new bridge fouled the old down (in use) line. It was discovered that by accepting a 15-chain curve immediately outside the old down portal, and a 19-chain radius connection west of the bridge, there was just sufficient room to slew the old down bridge clear of the essential decking for the new bridge. This allowed both new tracks to be laid over the new bridge, ready for the complete change-over of traffic to the new tunnel on full electrification, without undue disruption of the service on the old line.

Contract

Reports indicate that the usual practice was to put out contracts such as these to tender. This was duly done, with a priced bill-of-quantities contract containing 363 items. There was also the usual rise and fall adjustment clause to allow for variations in labour and material costs. Seven Civil Engineering Contractors were invited to tender. Two declined completely, three returned priced tenders as invited and the remaining two submitted the bill-of-quantities totalled and submitted as a target. In short, it was apparent that contractors were only prepared to accept the possibly high risks if fully protected by quoting high rates. After many adjustments to the terms, Messrs Balfour Beatty (the original contractors engaged for the repair of the old bores) were awarded the contract.

Information on the tunnelling can be found in the article " Woodhead - the Boring bit "

- - - © 2007 Philip Weston - - -